1����、序言

大型鍛件的調(diào)質(zhì)處理往往比小鍛件的熱處理更加困難����,某大型環(huán)形薄壁鍛件尾環(huán)殼體(以下簡(jiǎn)稱(chēng) “工件”)是固體火箭發(fā)動(dòng)機(jī)上的核心零件��。在發(fā)動(dòng)機(jī)運(yùn)行過(guò)程中����,工件一方面要支撐擴(kuò)張段絕熱層����,增加其強(qiáng)度��;另一方面��,對(duì)于柔性噴管�,其擺動(dòng)時(shí)殼體大端還要承受伺服作動(dòng)器作用的集中力。同時(shí)�,其剛度還要滿足伺服作動(dòng)器的控制精度�。該工件直徑較大����,厚度較薄�,調(diào)質(zhì)過(guò)程中易變形,且變形后無(wú)法進(jìn)行校正����。另外,其硬度要求較高,且不允許多次淬火����。本文從熱處理工藝、工裝設(shè)計(jì)和生產(chǎn)過(guò)程三個(gè)方面進(jìn)行探討�,從工藝和工裝適用性方面����,來(lái)提高工件的整體質(zhì)量。

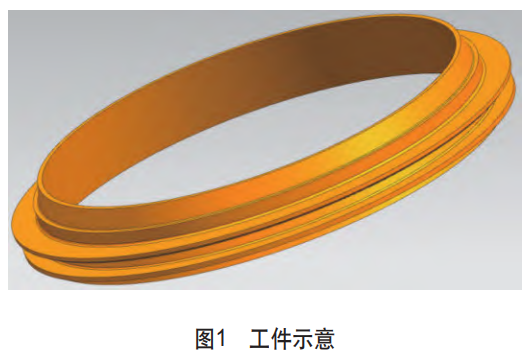

2����、工件介紹

工件材質(zhì)為 30CrMnSiA 鋼��,最大直徑為 1630mm����,高為 230mm,壁厚約 25mm����。

技術(shù)要求:硬度 33~38HRC��。

變形要求:翹曲變形不得超過(guò) 3.28mm�。

表面質(zhì)量:不允許存在麻點(diǎn)、裂紋等缺陷��。

30CrMnSiA 鋼的化學(xué)成分見(jiàn)表 1。

表 1 30CrMnSiA 鋼的化學(xué)成分(質(zhì)量分?jǐn)?shù) %)

| C | Cr | Mn | Si | P | S |

| 0.28~0.34 | 0.80~1.10 | 0.80~1.10 | 0.90~1.20 | ≤0.02 | ≤0.02 |

3�、工藝制定

大型鍛件的調(diào)質(zhì)多數(shù)情況下是作為最終熱處理��,賦予大型鍛件的最終性能。因此,對(duì)其進(jìn)行熱處理必須嚴(yán)謹(jǐn)�,大鍛件的內(nèi)部存在較多缺陷��,鍛件的尺寸和重量越大�,合金成分越多,缺陷問(wèn)題就越嚴(yán)重。本文所討論的就是關(guān)于 30CrMnSiA 鋼的大型環(huán)形鍛件的調(diào)質(zhì)處理����。

3.1 淬火工藝

(1)淬火溫度:與小鍛件相比����,大型鍛件熱處理過(guò)程中更容易出現(xiàn)問(wèn)題,其內(nèi)部存在較多的冶金缺陷,對(duì)于整只鋼錠鍛造成的鍛件�,加熱時(shí)往往采用規(guī)定溫度的上限 [1]。

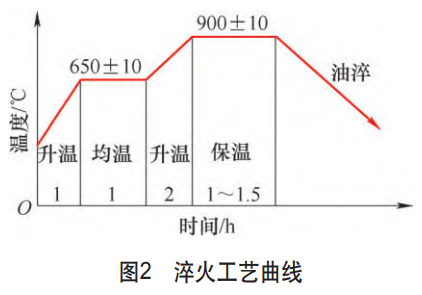

(2)加熱方式:在大型鍛件進(jìn)行熱處理時(shí),對(duì)其有效截面尺寸進(jìn)行計(jì)算分析,控制好裝爐溫度和加熱速度�。通常對(duì)于有效截面尺寸小的鍛件����,裝爐時(shí)不限制升溫速度����。對(duì)于合金元素含量高的鍛件�,必須選擇階梯加熱的方式。按照常規(guī)熱處理經(jīng)驗(yàn),選定 650℃為中間均溫溫度。

(3)均溫與保溫:當(dāng)儀表到達(dá)工藝溫度時(shí),就意味著均溫開(kāi)始�。一般均溫時(shí)間選擇 1~1.5 倍保溫時(shí)間。保溫時(shí)間的選取則按照工件的有效截面尺寸來(lái)確定,保溫時(shí)間一般按 0.8~1.0h/100mm 選取�。中高合金鋼取上限,低合金鋼取下限。該工件淬火工藝的淬火溫度階段的保溫時(shí)間為 1~1.5h�。

(4)淬火冷卻:大型鍛件淬火時(shí),首先最關(guān)鍵在于冷卻速度,其次是終冷溫度 [2]��。對(duì)于合金鋼鍛件�,一般選擇油淬,鍛件在油中冷卻速度比在水中小�,因此工件內(nèi)外溫差小��,可顯著減小工件開(kāi)裂和變形的傾向����。淬火冷卻時(shí)間很大程度上決定了工件的熱處理效果��,若時(shí)間過(guò)短,則工件性能達(dá)不到所需要求����;若時(shí)間過(guò)長(zhǎng)��,終冷溫度過(guò)低����,則會(huì)加大工件淬裂的危險(xiǎn)性 [3]。終冷溫度與工件的內(nèi)在質(zhì)量有關(guān),為此選取 50~80℃為終冷溫度。

基于以上分析��,該工件最終淬火工藝相關(guān)參數(shù)為 900±10℃油淬,經(jīng)歷升溫均溫、升溫����、保溫階段�,保溫時(shí)間 1~1.5h。

3.2 回火工藝

大型鍛件淬火后應(yīng)及時(shí)回火,防止工件開(kāi)裂�,原則是不超過(guò) 2h�。淬火后回火是為了獲得最終力學(xué)性能,并消除內(nèi)應(yīng)力�,獲得穩(wěn)定的回火組織 [4]��,以達(dá)到工件的技術(shù)要求����。

(1)回火溫度選擇:大型鍛件的回火溫度依照組織����、性能的要求確定,可以進(jìn)行工藝試驗(yàn)再確定回火溫度�。

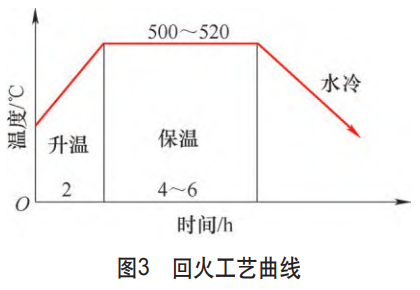

(2)回火均溫����、保溫時(shí)間:大型鍛件回火時(shí)��,應(yīng)依據(jù)工件形狀的復(fù)雜程度來(lái)控制升溫速度,有時(shí)為了防止工件中缺陷擴(kuò)大�,在 350℃保持一定的時(shí)間�,然后再升高到工件回火溫度 [5]。工件回火保溫時(shí)間一般是與工件有效截面有關(guān)��,在 300~600℃回火時(shí),空氣爐中的保溫時(shí)間為 40~60min 加上最大厚度乘以 2~3min/mm����。該工件回火工藝的總保溫時(shí)間為均溫時(shí)間加上保溫時(shí)間����,共 4~6h����。

(3)回火冷卻:對(duì)于 30CrMnSiA 鋼�,回火冷卻選用水冷或油冷均可�。通常冷卻速度為:水冷 > 油冷 > 空冷 > 爐冷,隨著冷卻速度的增大,洛氏硬度逐漸增大,沖擊韌度逐漸提高�。為獲得較高硬度�,回火采用水冷方式����。

該工件最終回火工藝相關(guān)參數(shù)為 500~520℃水冷��,經(jīng)歷升溫�、保溫階段��,保溫時(shí)間 4~6h����。

3.3 爐型的選擇

根據(jù)工藝要求及工件尺寸大小�,選擇型號(hào)為 RT3-265-10 的全纖維臺(tái)車(chē)爐,該設(shè)備為 Ⅲ 類(lèi)爐����,額定溫度為 1000℃��,額定功率為 265kW�,有效尺寸為 2200mm×1800mm×900mm,能夠滿足工藝的溫度范圍要求及工件的尺寸要求��。

4����、工裝設(shè)計(jì)

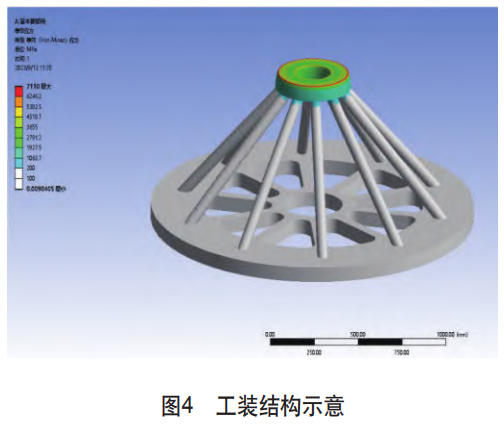

4.1 外形設(shè)計(jì)

由于工件呈環(huán)形,在高溫起吊過(guò)程中�,受到不均勻的力會(huì)導(dǎo)致工件嚴(yán)重變形�,因此在設(shè)計(jì)工裝時(shí),就設(shè)計(jì)成一個(gè)頂端起吊結(jié)構(gòu)形式。

工裝由上圓板、下圓板和鋼管焊接而成,頂端的圓板用于起吊。該外形工裝能夠?qū)ぜ鹑巫饔茫员WC工件在高溫起吊過(guò)程中均勻受力����,從而降低工件的變形量��。另外��,在起吊工件時(shí)����,鋼管焊接部分能夠?qū)ぜ鸬焦潭ㄗ饔?,保證工裝使用的安全性��。

4.2 強(qiáng)度計(jì)算

設(shè)計(jì)的工裝要進(jìn)行強(qiáng)度計(jì)算,避免在高溫起吊過(guò)程中,工裝因受力過(guò)大失效����,而造成人員傷亡�。

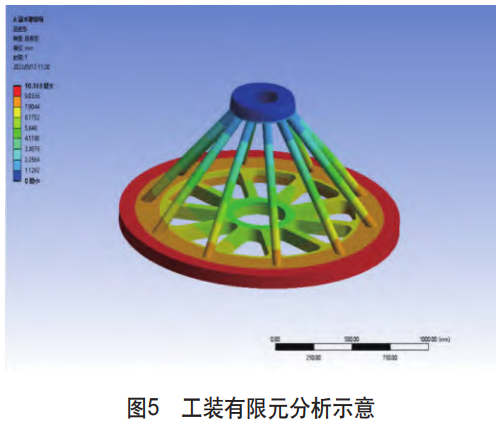

對(duì)工裝進(jìn)行有限元分析,邊界條件設(shè)置為工裝上表面起固定支撐,按照所承受工件重力��,對(duì)工裝下圓板上表面施加 2600N 的力,環(huán)境溫度按照工件淬火溫度設(shè)置,為 900℃。

經(jīng)過(guò)有限元分析計(jì)算����,工裝上圓板受力較小��,工裝下圓板受力較大�,若在下圓板受力最大位置放置工件��,則其變形量會(huì)達(dá)到 10.16mm�,但工裝是均勻變形,高溫起吊過(guò)程中仍然能夠?qū)ぜ鸬骄鶆蛑蔚淖饔?,因此工件的外形設(shè)計(jì)合格��。要使工裝變形量減小��,只需更換材料,將普通碳素鋼更換成耐高溫材料��,或增大下圓盤(pán)厚度,這些都能改善工裝在起吊過(guò)程中的變形問(wèn)題�,并延長(zhǎng)工裝的使用壽命�。

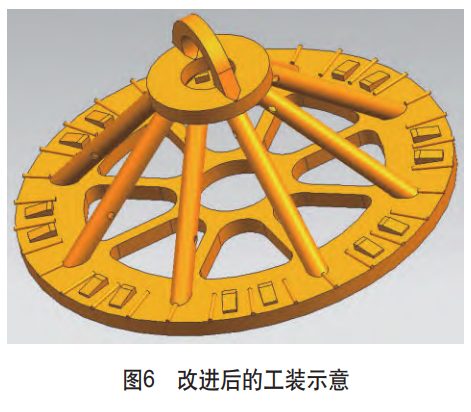

在后續(xù)的使用過(guò)程中,逐漸對(duì)工裝進(jìn)行改進(jìn)����,在工裝下圓盤(pán)上表面焊接相同尺寸的鐵棒�,在淬火時(shí)����,讓工件的底面能夠接觸到淬火冷卻介質(zhì)��,并添加不同尺寸的楔鐵作為調(diào)整工具��,以延長(zhǎng)工裝的使用壽命����。

5�、工件熱處理

5.1 生產(chǎn)操作

首先進(jìn)行來(lái)件檢測(cè),檢查工件表面是否有裂紋等明顯缺陷��,檢查是否存在尖角。

將工件放置在專(zhuān)用工裝上��,注意工件需平穩(wěn)放置��,工件底面需全接觸工裝�,無(wú)接觸部分采用楔鐵墊平����。工件和工裝一起進(jìn)爐加熱����,工裝在爐內(nèi)也需放置平穩(wěn)。起吊時(shí)需平穩(wěn)升起����,快速進(jìn)入油槽淬火����,注意冷卻時(shí)間�,終冷溫度控制在 50~80℃,淬火后需進(jìn)行硬度檢測(cè)�,為回火溫度的選擇提供數(shù)據(jù),淬火完成后應(yīng)及時(shí)回火����。

5.2 檢測(cè)結(jié)果

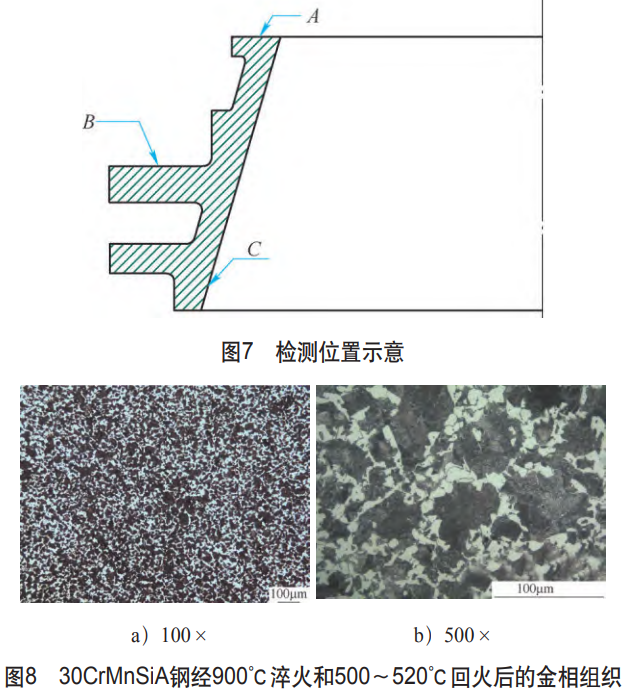

采用此工藝和工裝��,調(diào)質(zhì)完成 6 件工件,依次對(duì)其進(jìn)行硬度和翹曲變形檢測(cè)����,并對(duì)同爐試樣采用光學(xué)顯微鏡進(jìn)行金相分析�。硬度檢測(cè)淬火硬度和回火硬度,檢測(cè)設(shè)備使用便攜式硬度計(jì),檢測(cè)點(diǎn)位為圓周方向 90°����,間隔檢測(cè)小端 A 面和大端 B 面共 4 點(diǎn)�;變形檢測(cè)工件小端 A 面�、大端 B 面及內(nèi)錐面 C 面,每面檢測(cè) 8 個(gè)點(diǎn)位,沿圓周方向均勻分布。

30CrMnSiA 鋼經(jīng) 900℃淬火和 500~520℃回火后的金相組織均勻�。

硬度和翹曲變形檢測(cè)數(shù)據(jù)統(tǒng)計(jì)分別見(jiàn)表 2 和表 3。

表 2 硬度檢測(cè)數(shù)據(jù)統(tǒng)計(jì)(HRC)

| 工件編號(hào) | 檢測(cè)點(diǎn) | 檢測(cè)點(diǎn) |

| A1 | B1 | A2 | B2 | A1 | B1 | A2 | B2 |

| 1# | 45.2 | 43.6 | 45.8 | 44.1 | 36.8 | 35.7 | 37.6 | 36.1 |

| 2# | 45.5 | 44.3 | 45.7 | 44.2 | 37.2 | 36.5 | 37.1 | 36.3 |

| 3# | 46.2 | 45.4 | 45.6 | 45.3 | 38.0 | 37.3 | 37.4 | 37.2 |

| 4# | 44.8 | 45.6 | 45.8 | 43.6 | 36.8 | 37.5 | 37.8 | 35.4 |

| 5# | 45.2 | 44.6 | 44.1 | 44.3 | 37.1 | 36.7 | 36.3 | 36.4 |

| 6# | 45.5 | 43.9 | 45.6 | 45.6 | 37.3 | 35.7 | 37.5 | 37.1 |

表 3 翹曲變形檢測(cè)數(shù)據(jù)統(tǒng)計(jì)(mm)

| 工件編號(hào) | 檢測(cè)面 | 檢測(cè)點(diǎn) |

|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1# | A | 1.2 | 1.7 | 1 | 0.3 | 1.3 | 2 | 0.8 | 0.6 |

| B | 0.2 | 1 | 1 | 1.7 | 1.6 | 0 | 2 | 2.7 |

| C | 1.5 | 1 | 1.2 | 1.1 | -0.3 | 0 | 1 | 1.2 |

| 2# | A | 1.1 | 1.6 | 1.2 | 0.3 | 1.2 | 1.1 | 0.5 | 1.1 |

| B | 1.2 | 1.8 | 1.2 | 0.3 | 1.8 | 1.8 | 0.4 | 0.1 |

| C | 1.4 | 1.9 | 1.3 | -0.1 | 1.7 | 1.5 | -0.2 | 0 |

| 3# | A | 1.3 | 1.5 | 0.3 | 1.3 | 1.5 | 0.4 | 0.1 | 1.6 |

| B | 1.3 | 1.8 | 1.5 | 2 | 3 | 0.4 | 1.6 | 0.1 |

| C | 1.4 | 1 | 1.3 | 1.5 | 0.7 | -1.4 | 0.2 | 0.5 |

| 4# | A | 0.2 | 1.3 | 1.8 | 1.9 | 1 | 1.6 | 0.7 | 2 |

| B | 1.9 | 2.1 | 0.3 | 0.8 | 1.5 | 0.7 | 2.3 | 1.6 |

| C | 0.3 | 0.8 | -0.1 | 0.3 | 0.8 | 1.1 | 1.3 | 1.1 |

| 5# | A | 1.5 | 1.8 | 0.9 | 1.2 | 2 | 1.6 | 0.7 | 1.4 |

| B | 0.8 | 1.2 | 2.2 | 1.6 | 1.7 | 0.4 | 1.8 | 1.5 |

| C | 1.1 | 1.6 | 1.5 | 0.4 | 0.7 | 1.3 | 0.6 | 0.5 |

| 6# | A | 2.1 | 1.5 | 1.8 | 1.3 | 2.2 | 0.8 | 1.3 | 1 |

| B | 1.5 | 0.6 | 1.3 | 1.1 | 1.6 | 1.3 | 0.9 | 0.4 |

| C | 1.5 | 1.2 | 0.8 | 0.9 | -0.2 | 1.4 | 1.5 | 0.5 |

由表 2 可知,A 面淬火和回火后硬度普遍高于 B 面,且回火后所有工件硬度均控制在 35~38HRC��,滿足工件 33~38HRC 的要求�。

由表 3 可知,3# 工件 B 面的第 5 點(diǎn)變形量最大,達(dá)到 3mm����,在要求的 3.28mm 范圍內(nèi)����。

從金相組織可看出��,經(jīng) 900℃淬火和 500~520℃回火后的金相檢測(cè)組織為均勻的回火索氏體。

6、結(jié)束語(yǔ)

1)大型環(huán)形鍛件在熱處理過(guò)程中極容易變形��,且有效壁厚越薄,變形量越大�。淬火時(shí)采用階梯式升溫的方法可有效減小熱應(yīng)力�。

2)裝爐方式對(duì)工件的變形量有較大影響,因此裝爐時(shí)應(yīng)注意工件或工裝是否能夠全面接觸熱處理爐支撐平臺(tái)�,保證加熱時(shí)受力均勻����。

3)工件在淬火起吊時(shí)需平穩(wěn)��,保證起吊過(guò)程受力均勻����,淬火時(shí)控制好油淬時(shí)間����,掌握終冷溫度,淬火后還需檢測(cè)淬火硬度,且淬火后盡快開(kāi)始回火����。

參考文獻(xiàn)

[1] 耿學(xué)明����,黎定旺。大型鍛件的調(diào)質(zhì)熱處理實(shí)踐 [J]. 金屬加工 (熱加工),2010 (5):40 - 41,45.

[2] 李曉宏����,楊迪�,黃守己。大型環(huán)類(lèi)鍛件調(diào)質(zhì)處理 [J]. 大型鑄鍛件,2018 (2):26 - 27,35.

[3] 沈黃富。關(guān)于大型鍛件調(diào)質(zhì)熱工藝的探討 [J]. 金屬熱處理�,1982 (8):27 - 33.

[4] 齊加勝��。淬回火對(duì) 30CrMnSiA 高強(qiáng)鋼組織與力學(xué)性能的影響 [J]. 熱加工工藝,2022,51 (24):125 - 128.

[5] 吳子愷,陳偉����,周海銘����,等����。回火溫度對(duì) 30CrMnSiA 鋼力學(xué)性能的影響 [J]. 金屬熱處理��,2019,44 (4):163 - 167.

相關(guān)鏈接