鈦法蘭作為石油化工、天然氣輸送、航空航天等領(lǐng)域不可或缺的連接部件,其性能直接決定了承壓設(shè)備的安全性與可靠性。隨著工業(yè)設(shè)備向大型化、高壓化發(fā)展,法蘭設(shè)計(jì)逐漸突破傳統(tǒng)標(biāo)準(zhǔn)范圍,對密封性能、結(jié)構(gòu)強(qiáng)度及防腐技術(shù)提出了更高要求。從高壓設(shè)備的八角墊密封到鈦合金法蘭的精密加工,從傳統(tǒng)華脫斯計(jì)算方法到基于泄漏率準(zhǔn)則的現(xiàn)代設(shè)計(jì)理念,法蘭技術(shù)正朝著精準(zhǔn)化、高效化、長壽命方向演進(jìn)。

密封失效與腐蝕是法蘭連接的主要失效模式。墊片作為密封核心元件,其性能參數(shù)(如墊片系數(shù)、密封應(yīng)力)與法蘭結(jié)構(gòu)設(shè)計(jì)、螺栓預(yù)緊力存在復(fù)雜耦合關(guān)系;而在潮濕、腐蝕性環(huán)境中,法蘭及螺栓的腐蝕會導(dǎo)致預(yù)緊力損失與密封失效,因此防腐技術(shù)的選擇與施工管理至關(guān)重要。此外,特殊材料(如鈦及鈦合金)的法蘭加工工藝,需兼顧材料特性與成形精度,以滿足高端領(lǐng)域的嚴(yán)苛要求。

本文基于四篇相關(guān)研究論文,系統(tǒng)整合了法蘭的優(yōu)化設(shè)計(jì)方法、密封與計(jì)算技術(shù)、加工工藝及防腐措施。通過分析不同場景下的技術(shù)要點(diǎn)與應(yīng)用案例,總結(jié)法蘭設(shè)計(jì)-制造-防腐的協(xié)同優(yōu)化策略,為工程實(shí)踐提供理論參考與技術(shù)指導(dǎo)。

1、法蘭設(shè)計(jì)基礎(chǔ)與優(yōu)化方法

1.1大直徑高壓法蘭的設(shè)計(jì)挑戰(zhàn)

大直徑高壓法蘭(如DN1200mm、Class900級)的設(shè)計(jì)常超出GB/T13402、HG/T20592等標(biāo)準(zhǔn)范圍,需通過定制化計(jì)算確保安全。以某海上平臺過濾分離器為例,其設(shè)計(jì)壓力13.2MPa、溫度70℃,法蘭材料為16MnⅣ,筒體采用Q345R(厚度54mm),傳統(tǒng)管法蘭直接應(yīng)用存在三大問題[1]:

密封形式不匹配:突面密封無法滿足高壓需求,需改為環(huán)形連接面+八角墊密封;

螺栓配置不合理:大規(guī)格螺栓(M100)導(dǎo)致法蘭錐頸應(yīng)力超標(biāo);

應(yīng)力分布失衡:原設(shè)計(jì)錐頸軸向應(yīng)力258.97MPa,超過許用值250.5MPa,組合應(yīng)力σHT達(dá)196.14MPa,超出167MPa限值[1]。

此類法蘭的設(shè)計(jì)核心在于平衡強(qiáng)度、剛度與密封性:強(qiáng)度不足會導(dǎo)致法蘭塑性變形,剛度不足則因轉(zhuǎn)角過大破壞墊片密封,而密封失效直接引發(fā)介質(zhì)泄漏。

1.2密封元件與螺栓系統(tǒng)優(yōu)化

1.2.1墊片選型與尺寸設(shè)計(jì)

高壓場景下,八角墊憑借徑向自緊性和重復(fù)使用性優(yōu)于橢圓墊與金屬纏繞墊。其密封原理是通過梯形槽與八角墊的金屬接觸,形成線密封效應(yīng),墊片系數(shù)m和比壓力y顯著高于非金屬墊片(如m=3.0-4.5,y=60-100MPa)[1]。以R105型八角墊為例,其截面尺寸需與法蘭梯形槽匹配(槽角23°±0.5°,深度36.53mm),中心圓直徑的確定需通過力矩分析優(yōu)化——當(dāng)墊片中心圓直徑為1380mm時,法蘭計(jì)算力矩最小(約3800kN.m),此時密封應(yīng)力分布最均勻[1]。

1.2.2螺栓配置策略

螺栓總截面積需同時滿足預(yù)緊與操作狀態(tài)需求,計(jì)算公式為:

An1=Wn1/Sa,An2=Wn2/Sb

其中,Wn1為預(yù)緊載荷,Wn2為操作載荷,Sa、Sb分別為常溫與設(shè)計(jì)溫度下的螺栓許用應(yīng)力[1]。以35CrMoA螺栓為例,對比不同規(guī)格配置(表1),M80×28的組合最優(yōu):總截面積129546.9mm2,裕量22.5%,既避免M100的材料浪費(fèi),又減少M(fèi)76的螺栓數(shù)量(32個)導(dǎo)致的操作空間不足[1]。

| 螺栓規(guī)格 | 數(shù)量 | 中心圓直徑 (mm) | 總截面積 (mm2) | 裕量 (%) |

| M100 | 24 | 1587.5 | 176449.6 | 66.8 |

| M80 | 28 | 1600.0 | 129546.9 | 22.5 |

| M76 | 32 | 1632.0 | 133023.8 | 25.8 |

1.3法蘭結(jié)構(gòu)尺寸的調(diào)整與驗(yàn)證

鈦法蘭應(yīng)力(錐頸軸向應(yīng)力σH、環(huán)向應(yīng)力σT、徑向應(yīng)力σR)對結(jié)構(gòu)尺寸敏感,需通過參數(shù)迭代優(yōu)化:

錐頸大端厚度δ?:增大δ?可顯著降低σH(每增加10mm,σH下降約20MPa),原設(shè)計(jì)δ?=80mm時σH=258.97MPa,調(diào)整至102mm后σH降至173.58MPa[1];

法蘭環(huán)厚度δf:減小δf可降低σR,但需避免過度減薄導(dǎo)致剛度不足。原設(shè)計(jì)δf=233.4mm時σR=46.95MPa,優(yōu)化至200mm后σR=90.45MPa,仍低于許用值167MPa[1];

剛度校核:優(yōu)化后法蘭剛度指數(shù)J=0.613<1,滿足ASMEⅧDiv.1附錄2要求,確保操作中墊片應(yīng)力不流失[1]。

優(yōu)化后法蘭質(zhì)量減少130kg,外徑縮小25mm,實(shí)現(xiàn)了安全與經(jīng)濟(jì)性的平衡。

2、法蘭密封原理與計(jì)算方法

2.1墊片性能參數(shù)與密封機(jī)理

墊片的密封性能由壓縮性、回彈率、密封應(yīng)力共同決定。華脫斯法采用m(墊片系數(shù))和y(最小比壓力)描述其特性,其中m特性,其中m反映操作狀態(tài)下維持密封所需的應(yīng)力放大系數(shù),y為預(yù)緊時的初始密封應(yīng)力[3]。例如,金屬八角墊的y值約60MPa,意味著預(yù)緊時需至少施加60MPa的密封應(yīng)力才能實(shí)現(xiàn)初始密封[1]。

現(xiàn)代設(shè)計(jì)方法更強(qiáng)調(diào)泄漏率與墊片應(yīng)力的定量關(guān)系。PVRC方法定義密封等級Tp(如T1=0.2對應(yīng)經(jīng)濟(jì)級,T3=0.00002對應(yīng)緊密級),通過試驗(yàn)確定墊片系數(shù)Gb、a、Gs,其中Gb為初始密封所需最小應(yīng)力,Gs為操作狀態(tài)下的殘留應(yīng)力需求[3]。EN1591法則進(jìn)一步引入QMIN(預(yù)緊最小應(yīng)力)、QSMIN(操作最小應(yīng)力)等6個參數(shù),考慮墊片蠕變與溫度差的影響[3]。

2.2主流法蘭計(jì)算方法對比

2.2.1華脫斯法(ASMEⅧDiv.1)

核心假設(shè):將法蘭視為彈性基礎(chǔ)梁,忽略預(yù)緊與操作狀態(tài)的載荷關(guān)聯(lián),通過校核σH≤1.5[σ]f、σR≤[σ]f、σT≤2[σ]f-σH確保強(qiáng)度[3];

局限性:未考慮泄漏率,墊片系數(shù)m、y基于經(jīng)驗(yàn)推薦,無法量化密封性能,適用于低壓常規(guī)場景[3]。

2.2.2PVRC方法

創(chuàng)新點(diǎn):引入泄漏率準(zhǔn)則,通過Tp值關(guān)聯(lián)內(nèi)壓與允許泄漏率(如Tp=0.002對應(yīng)標(biāo)準(zhǔn)級密封),螺栓載荷計(jì)算需同時滿足預(yù)緊與操作狀態(tài)的墊片應(yīng)力需求[3];

應(yīng)用:需通過ROTT試驗(yàn)獲取Gb、a、Gs參數(shù),適用于中高壓密封要求嚴(yán)格的場合(如化工反應(yīng)器)[3]。

2.2.3EN1591方法

系統(tǒng)視角:將法蘭-螺栓-墊片視為整體,考慮變形協(xié)調(diào)與蠕變,采用極限載荷法校核強(qiáng)度(載荷比IL≤1),密封等級按泄漏率分為L1.0(≤1.0mg/s/mm)、L0.1等[3];

復(fù)雜性:需6個墊片參數(shù)與迭代計(jì)算,依賴軟件實(shí)現(xiàn),適用于歐洲標(biāo)準(zhǔn)體系下的高端設(shè)備[3]。

三種方法的核心差異如表 2 所示:

| 方法 | 墊片參數(shù) | 密封評價指標(biāo) | 強(qiáng)度校核準(zhǔn)則 | 適用場景 |

| 華脫斯法 | m、y | 無 | 彈性應(yīng)力限值 | 低壓常規(guī)法蘭 |

| PVRC 方法 | Gb、a、Gs | Tp 值 | 彈性應(yīng)力 + 密封等級 | 中高壓密封敏感場合 |

| EN 1591 法 | QMIN、QSMIN 等 | 泄漏率等級 | 極限載荷比 + 法蘭轉(zhuǎn)角 | 歐洲體系高端設(shè)備 |

2.3計(jì)算方法的工程應(yīng)用選擇

標(biāo)準(zhǔn)內(nèi)法蘭:優(yōu)先采用華脫斯法,直接引用標(biāo)準(zhǔn)中的m、y值(如HG/T20592),簡化設(shè)計(jì);

高壓大直徑法蘭:需結(jié)合PVRC方法,通過泄漏率試驗(yàn)確定墊片參數(shù),確保σH、σT等應(yīng)力同時滿足強(qiáng)度與密封要求[1,3];

跨國項(xiàng)目:按項(xiàng)目標(biāo)準(zhǔn)選擇,如ASME項(xiàng)目可用華脫斯法+PVRC補(bǔ)充,EN項(xiàng)目需采用EN1591法[3]。

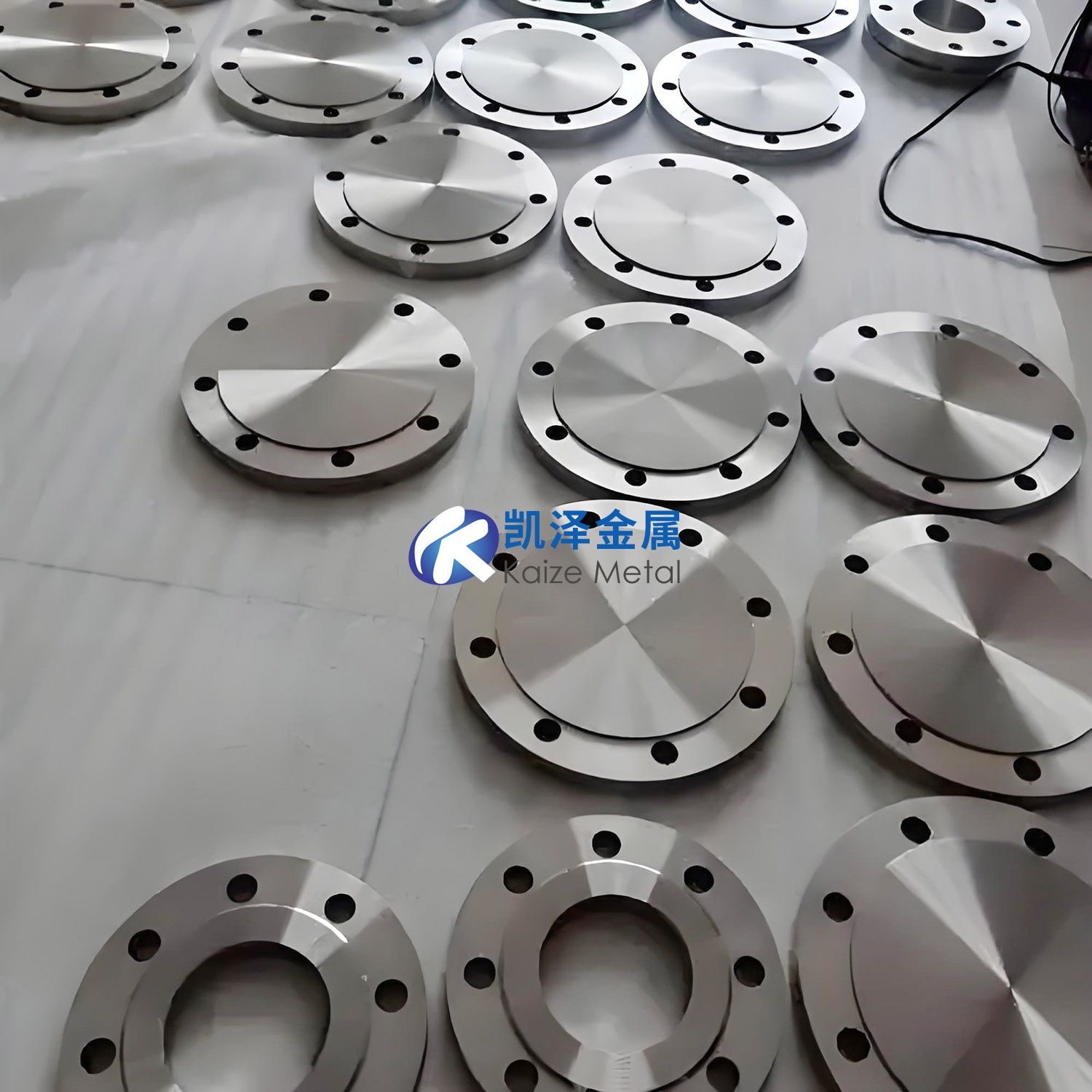

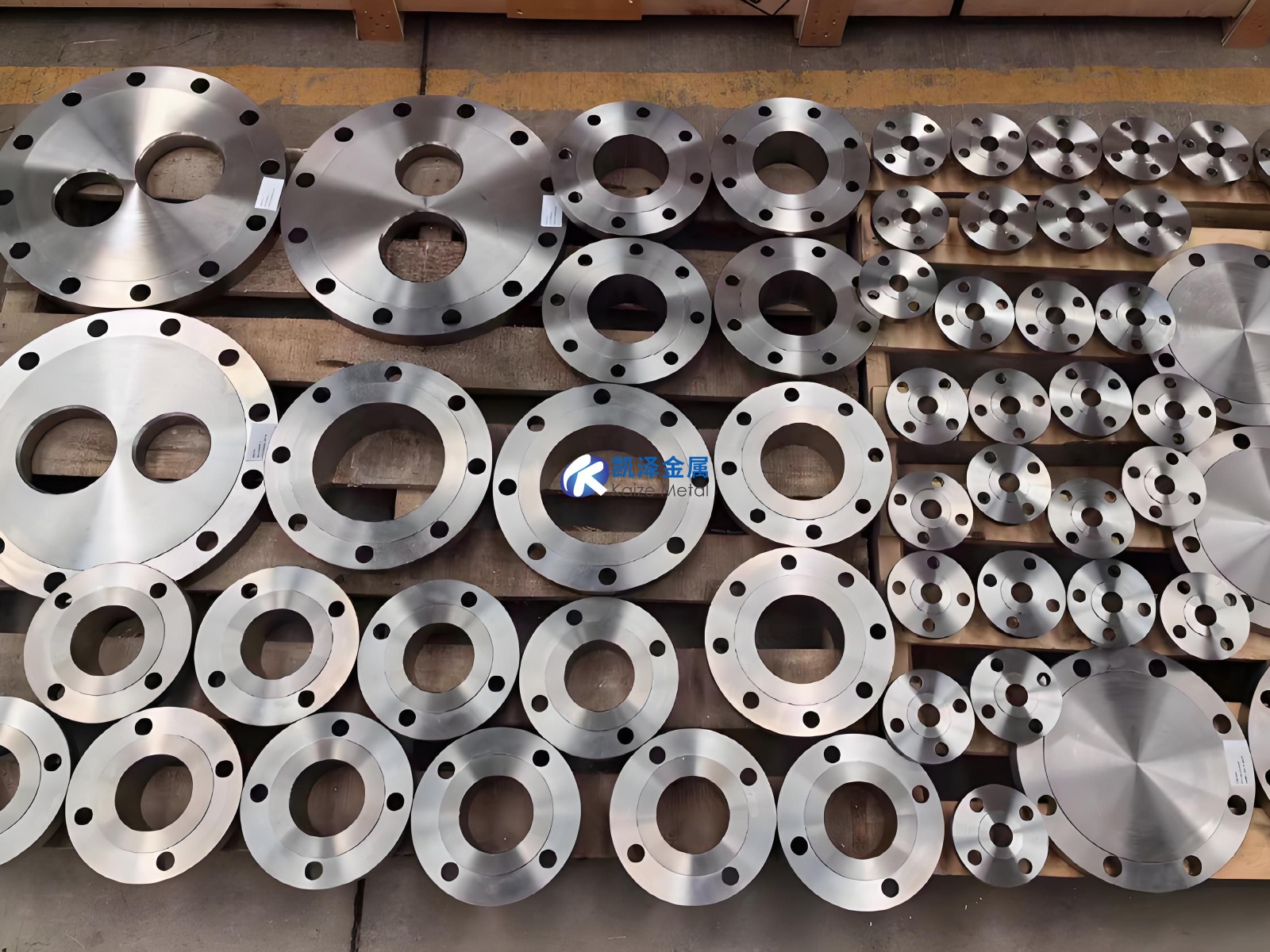

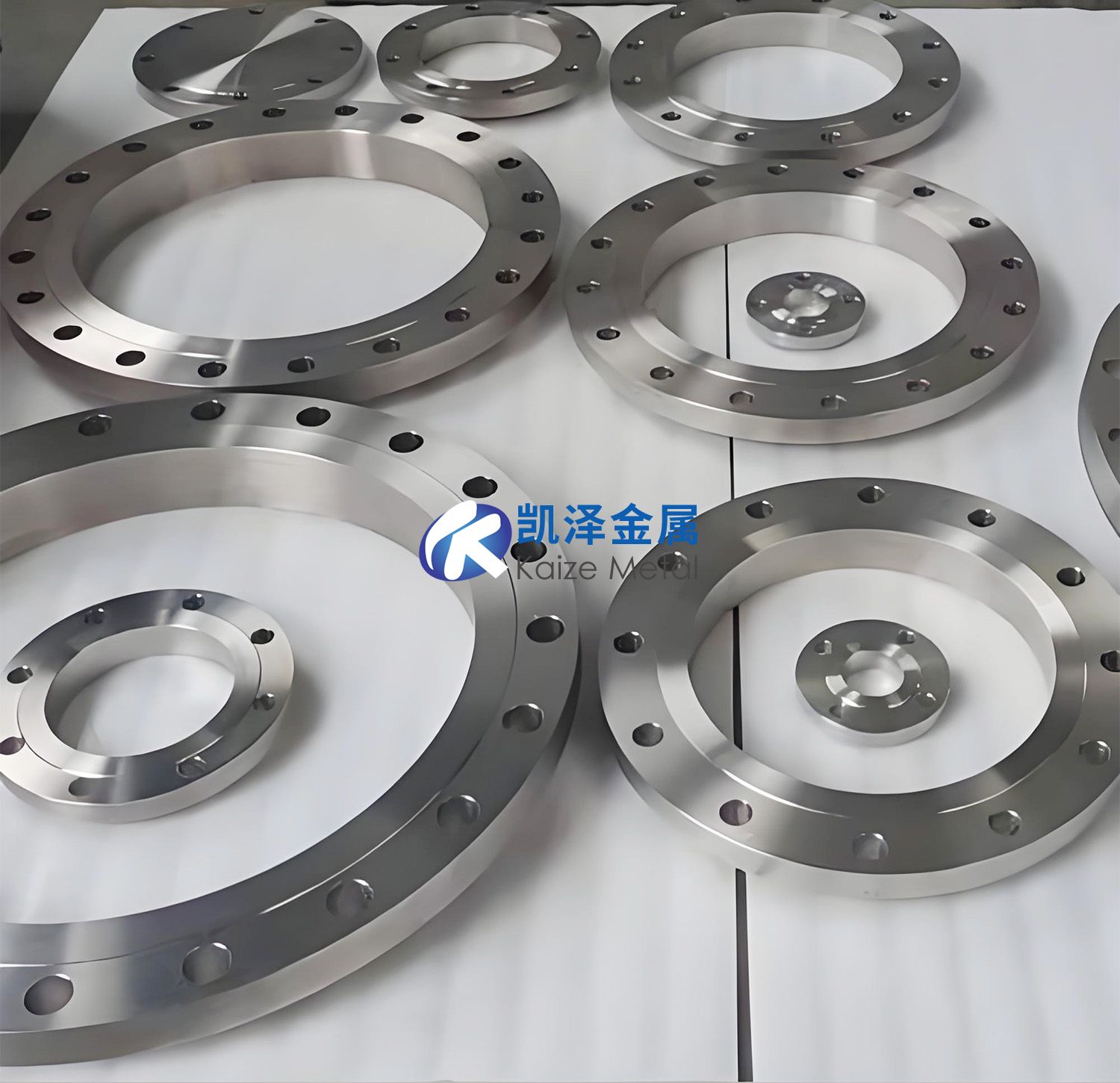

3、法蘭加工工藝與材料特性

3.1鈦及鈦合金法蘭的加工挑戰(zhàn)

鈦及鈦合金(如TC4)具有高強(qiáng)度、耐腐蝕性,但高溫下易氧化,導(dǎo)致表面硬化與加工裂紋,傳統(tǒng)自由鍛造或模鍛難以滿足宇航標(biāo)準(zhǔn)(如金屬結(jié)晶致密性、探傷要求)[4]。其加工難點(diǎn)包括:

氧化敏感:500℃以上加熱時,表面形成TiO?硬層,導(dǎo)致鍛造時折疊與開裂;

成形難度大:鈦合金塑性差,大變形量下易出現(xiàn)局部應(yīng)力集中[4]。

3.2鈦合金法蘭的擠壓成型工藝

3.2.1工藝步驟

表面保護(hù):中空鈦錠外包0.8mm銅板(鈦合金需加包同厚度不銹鋼板),焊接固定以隔絕空氣,防止氧化[4];

加熱擠壓:加熱至500℃以上,通過大型油壓/水壓擠壓機(jī)一次性成型管型坯料,擠壓時使用玻璃保護(hù)潤滑劑減少摩擦[4];

精整加工:管坯按法蘭厚度線切割或帶鋸切片,經(jīng)銑削、鉆孔等精加工后檢驗(yàn)(探傷、力學(xué)性能測試)[4]。

3.2.2工藝優(yōu)勢

組織致密:擠壓使金屬結(jié)晶充分結(jié)合,抗拉強(qiáng)度提升10%-15%,滿足宇航標(biāo)準(zhǔn)對高低倍組織的要求;

成本降低:減少鍛造后的裂紋修復(fù)環(huán)節(jié),材料利用率從傳統(tǒng)工藝的50%提升至80%[4];

效率提升:擠壓成型減少多道次鍛造,加工周期縮短30%[4]。

3.3 不同材料法蘭的工藝對比

| 材料 | 加工工藝 | 關(guān)鍵控制參數(shù) | 適用領(lǐng)域 |

| 碳鋼 / 低合金鋼 | 自由鍛 + 機(jī)加工 | 鍛造溫度 1100-1250℃ | 常規(guī)壓力管道 |

| 不銹鋼 | 模鍛 + 固溶處理 | 冷卻速度≥50℃/s(防晶間腐蝕) | 耐腐蝕場合 |

| 鈦合金 | 擠壓成型 + 精整 | 加熱溫度 500-800℃,表面保護(hù) | 航空航天、高端化工 |

4、法蘭防腐技術(shù)與施工管理

4.1天然氣管道法蘭的腐蝕環(huán)境

天然氣管道法蘭及螺栓面臨多重腐蝕因素:

介質(zhì)腐蝕:天然氣中的H?S、CO?形成酸性環(huán)境,導(dǎo)致電化學(xué)腐蝕;

環(huán)境影響:潮濕氣候(如沿海地區(qū))加速螺栓銹蝕,溫度波動產(chǎn)生的冷凝水加劇局部腐蝕;

應(yīng)力腐蝕:預(yù)緊力與腐蝕介質(zhì)共同作用,可能引發(fā)螺栓應(yīng)力腐蝕開裂[2]。

腐蝕會導(dǎo)致螺栓預(yù)緊力損失(每年可達(dá)5%-10%),墊片密封應(yīng)力下降,最終引發(fā)泄漏[2]。

4.2包裹防腐技術(shù)的應(yīng)用

4.2.1材料選擇

采用Stopaq粘性防腐材料,其由丁基橡膠與緩蝕劑組成,具有自修復(fù)性和密封性,能有效隔絕水、氧氣與腐蝕性氣體[2]。相比傳統(tǒng)黃油或油漆,其優(yōu)勢在于:

容錯率高:輕微破損后可自行愈合;

耐久性強(qiáng):使用壽命達(dá)15年以上,遠(yuǎn)超油漆(3-5年)[2]。

4.2.2施工流程

預(yù)處理:

漏失測試:PVC帶包裹法蘭24小時后打孔,用可燃性氣體檢測儀確認(rèn)無泄漏;

表面處理:角磨機(jī)打磨法蘭及螺栓至Sa2.5級,去除銹蝕與氧化皮[2];

包裹施工:

順序:從法蘭中心向外依次包裹防腐膏、防腐帶、PVC外層,確保無氣泡與褶皺;

密封:法蘭邊緣需重疊包裹≥50mm,螺栓頭部完全覆蓋[2];

質(zhì)量控制:

外觀檢查:無鼓包、開裂,PVC帶貼合緊密;

記錄存檔:標(biāo)記法蘭編號、施工日期及材料用量[2]。

4.3施工管理與應(yīng)急措施

安全培訓(xùn):施工人員需熟悉HSE規(guī)程,佩戴防靜電服、呼吸器,現(xiàn)場配備可燃?xì)怏w報(bào)警器[2];

環(huán)境控制:雨天或相對濕度>85%時暫停施工,避免水分殘留影響粘結(jié)力;

應(yīng)急處理:發(fā)現(xiàn)包裹層鼓包時,需穿刺排氣(遠(yuǎn)離火源),重新清理并包裹[2]。

5、工程案例與技術(shù)展望

5.1高壓過濾分離器法蘭優(yōu)化案例

某海上平臺過濾分離器法蘭(DN1200mm,13.2MPa)經(jīng)優(yōu)化后:

應(yīng)力指標(biāo):σH=173.58MPa,σT=101.38MPa,均滿足許用值;

密封性能:八角墊+環(huán)形槽密封,經(jīng)1.5倍設(shè)計(jì)壓力水壓試驗(yàn)無泄漏;

經(jīng)濟(jì)性:單臺設(shè)備減重130kg,材料成本降低約8%[1]。

5.2天然氣管道法蘭防腐案例

大慶油田某輸氣管道采用Stopaq包裹防腐后:

腐蝕速率從0.12mm/年降至0.01mm/年;

法蘭泄漏率從0.5次/千臺?年降至0.03次/千臺?年[2]。

5.3技術(shù)發(fā)展趨勢

智能化設(shè)計(jì):基于有限元與機(jī)器學(xué)習(xí)的法蘭參數(shù)優(yōu)化,實(shí)現(xiàn)強(qiáng)度與密封的多目標(biāo)平衡;

新型材料:開發(fā)高回彈金屬墊片(如Inconel合金)與長效防腐材料(石墨烯改性涂層);

數(shù)字化監(jiān)測:在法蘭密封面植入光纖傳感器,實(shí)時監(jiān)測墊片應(yīng)力與泄漏狀態(tài)[3]。

6、全文總結(jié)

本文系統(tǒng)闡述了鈦法蘭設(shè)計(jì)、密封計(jì)算、加工工藝及防腐技術(shù)的核心要點(diǎn):

高壓法蘭優(yōu)化:通過八角墊選型、螺栓配置迭代及結(jié)構(gòu)尺寸調(diào)整(增大錐頸厚度、減小法蘭環(huán)厚度),可實(shí)現(xiàn)應(yīng)力平衡與材料節(jié)約;

密封計(jì)算方法:華脫斯法適用于常規(guī)場景,PVRC與EN1591法更適合密封敏感場合,需根據(jù)項(xiàng)目標(biāo)準(zhǔn)與泄漏要求選擇;

鈦合金加工:擠壓成型工藝結(jié)合表面保護(hù)(銅板+不銹鋼板),可滿足宇航級法蘭的組織與性能要求;

防腐技術(shù):Stopaq包裹法能有效隔絕腐蝕介質(zhì),施工中需嚴(yán)格控制漏失測試與表面預(yù)處理。

未來法蘭技術(shù)將向精準(zhǔn)化、智能化發(fā)展,通過多學(xué)科協(xié)同(材料、力學(xué)、防腐)提升其在極端工況下的可靠性與經(jīng)濟(jì)性。

參考文獻(xiàn)

[1]趙周林。大直徑高壓設(shè)備法蘭優(yōu)化設(shè)計(jì)[J].石油化工設(shè)備,2023,52(6):44-48.

[2]陳萬勇。天然氣管道法蘭及螺栓包裹防腐施工管理探討[J].全面腐蝕控制,2021,35(9):120-124.

[3]蔡暖姝。法蘭計(jì)算方法和墊片性能參數(shù)[J].石油化工設(shè)備技術(shù),2014,35(2):57-61.

[4]常榮波。鈦及鈦合金法蘭加工工藝[P].中國專利:CN101758369A,2010-06-30.

相關(guān)鏈接